Did you know that water hammer can cause pipe bursts and severe damage to plumbing systems? It’s true! Without proper protection, the shock waves from water hammer can eventually wear down your pipes, leading to expensive repairs. In fact, according to the EPA, up to 20% of home plumbing repairs are directly linked to water pressure issues like water hammer.

One of the simplest and most effective ways to prevent this problem is by installing an air chamber in your plumbing system. Air chambers are easy to install, and this guide will walk you through a DIY air chamber installation step by step. Not only will this project save you money by preventing future repairs, but it also keeps your home’s plumbing running smoothly and quietly.

In this guide, you’ll learn the tools you need, common mistakes to avoid, and how to ensure your air chamber remains functional over time. Let’s dive in and get started with your DIY air chamber installation!

What You’ll Need for DIY Air Chamber Installation

Before jumping into the actual installation, it’s important to gather all the necessary tools and materials. Fortunately, you don’t need anything too complicated for a DIY air chamber installation. Most of these tools are readily available at hardware stores, and if you’re a DIY enthusiast, you might already have them at home.

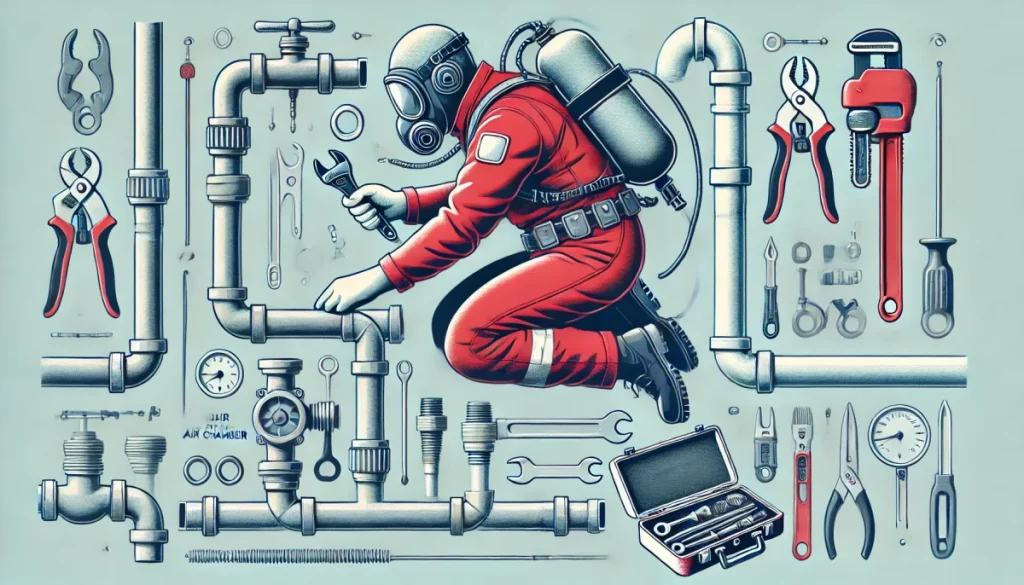

Here’s a quick checklist of what you’ll need:

- Pipe Wrench or Adjustable Wrench: This tool is crucial for tightening and loosening pipe connections. An adjustable wrench is ideal since it can adapt to different pipe sizes.

- Pipe Cutter: You’ll need this to cut the pipe where the air chamber will be installed. Make sure you choose the right type of cutter based on the pipe material (copper or PVC).

- Teflon Tape: Also known as plumber’s tape, this is essential for sealing threaded connections and preventing leaks.

- Copper or PVC Pipe: The type of pipe you use will depend on your home’s plumbing system. Copper is commonly used for water lines, but PVC is also a popular choice for newer installations.

- Air Chamber Kit or Pipe Cap: If you’re not building the air chamber from scratch, an air chamber kit will have everything you need. Alternatively, a pipe cap can be used to create a DIY air chamber.

- Plumber’s Tape: This helps reinforce connections, ensuring they are watertight.

Each tool has a specific purpose in the installation process. The pipe wrench helps you make tight connections, while the pipe cutter allows you to create precise cuts. Teflon tape seals the threads, ensuring no water leaks through the joints, and the air chamber kit or pipe cap will form the actual chamber that absorbs pressure surges. With these tools at your side, you’re well-prepared for a successful DIY air chamber installation.

Step-by-Step DIY Air Chamber Installation Guide

Now that you have all your tools ready, let’s dive into the installation process. Follow these steps carefully to ensure a smooth and effective installation.

Step 1: Turn Off the Water Supply

Before you begin, it’s critical to shut off the water supply to your home. Locate the main shut-off valve, usually found near the water meter, and turn it off. This step is important for two reasons: it prevents water from flooding the area while you work, and it reduces the pressure in the pipes, making it easier to cut and install the air chamber.

Once the water supply is off, open a few faucets around your home to drain any remaining water from the system. This will relieve the pressure and allow the pipes to empty, making the installation process safer and cleaner.

Step 2: Locate the Installation Point

The next step in your DIY air chamber installation is identifying where the air chamber should go. Ideally, the air chamber should be installed near a valve or faucet where water hammer is most likely to occur. This is typically at the end of a long run of pipe or near fixtures like washing machines, dishwashers, or outdoor spigots. These are areas where water pressure is prone to sudden changes, causing the loud banging sound known as water hammer.

If you’re unsure where to install the air chamber, a good rule of thumb is to place it near any valve that experiences frequent and sudden shutoffs. Once you’ve identified the spot, you’re ready to cut the pipe.

Step 3: Cut and Prepare the Pipe

Using your pipe cutter, make a clean, precise cut in the section of pipe where the air chamber will be installed. Take care to measure accurately before making the cut, as improper sizing can lead to alignment issues during installation. Once the pipe is cut, remove any burrs or sharp edges using sandpaper or a deburring tool. This ensures a smooth connection and helps prevent leaks later on.

If you’re working with copper pipes, make sure to clean the pipe ends with a pipe-cleaning brush to remove any oxidation. For PVC pipes, you’ll want to apply primer and solvent cement to ensure a strong bond between the pipe and the fittings.

Step 4: Install the Air Chamber

Now it’s time for the actual installation. If you’re using an air chamber kit, follow the manufacturer’s instructions for attaching it to the plumbing system. Most kits are designed to be screwed into place using threaded fittings, so you’ll need to apply Teflon tape to the threads before tightening them with your pipe wrench. This helps create a watertight seal.

If you’re making a DIY air chamber using a pipe cap, the process is similar. Insert the pipe cap at the top of the vertical section of pipe and secure it using the pipe wrench. Again, use Teflon tape to seal the threads and prevent any potential leaks.

Step 5: Turn On the Water and Test

Once the air chamber is securely installed, it’s time to turn the water back on. Slowly open the main shut-off valve and allow the water to flow back into the system. As the pipes refill, keep an eye out for any leaks around the area where the air chamber was installed.

Test the system by turning on the faucet or valve closest to the air chamber. If you hear no banging or knocking sounds, congratulations—you’ve successfully completed your DIY air chamber installation! If you do hear water hammer, it may be a sign that the air chamber isn’t properly aligned or that additional adjustments are needed.

Common Mistakes to Avoid During Installation

While a DIY air chamber installation is relatively straightforward, there are some common mistakes that can lead to problems down the road. Here are a few pitfalls to watch out for:

Misaligning the Air Chamber

One of the most common mistakes is misaligning the air chamber with the water line. If the chamber isn’t installed vertically, it may not be as effective at absorbing pressure surges. Make sure the air chamber is perfectly aligned to allow the air to compress and cushion the shock waves.

Over-Tightening or Under-Tightening Connections

Another mistake homeowners make is over-tightening or under-tightening the pipe connections. Over-tightening can strip the threads and cause leaks, while under-tightening may result in loose joints that don’t seal properly. The key is to tighten connections just enough to create a secure, watertight seal without damaging the threads.

Skipping Teflon Tape

Some DIYers skip the Teflon tape step, thinking it’s not necessary. This is a big mistake! Teflon tape helps create a seal between the threads and prevents leaks, so don’t forget to wrap it around the threads before making connections.

Avoiding these mistakes will ensure your DIY air chamber installation is successful and long-lasting.

Maintenance Tips After Installation

Once your DIY air chamber installation is complete, ongoing maintenance is key to keeping it functioning properly. The good news is that air chambers require very little upkeep, but there are a few things you can do to extend their lifespan.

Recharging the Air Chamber

Over time, the air in the chamber may dissolve into the water, reducing its effectiveness. To recharge the air chamber, simply follow the steps outlined in the installation process: turn off the water supply, drain the system, and allow air to refill the chamber.

Regular Inspections

It’s a good idea to inspect your air chamber every year or so for signs of wear or leaks. If you notice any issues, recharging the chamber or replacing worn parts can help keep your plumbing system running smoothly.

By performing these simple maintenance tasks, you can ensure your air chamber continues to protect your pipes from water hammer for years to come.

FAQs

-

Can I install an air chamber without turning off the water?

No, it’s important to turn off the water supply before starting the installation to prevent accidents and ensure a clean, safe work environment.

-

How long does it take to install an air chamber?

On average, a DIY air chamber installation takes about 1-2 hours, depending on your plumbing system and experience level.

-

Can air chambers be used in both old and new plumbing systems?

Yes, air chambers are compatible with both old and new systems, making them a versatile solution for preventing water hammer.

-

Do I need special skills for DIY air chamber installation?

Not at all! This is a beginner-friendly project that most homeowners can handle with basic plumbing tools.

-

What should I do if the air chamber doesn’t fix the water hammer problem?

If you still hear water hammer after installing the air chamber, check for misalignment or loose connections. If the problem persists, consider consulting a professional plumber for further diagnosis.

Conclusion

Installing an air chamber is one of the easiest and most effective ways to protect your plumbing system from the damaging effects of water hammer. With just a few tools and this step-by-step guide, you can complete a DIY air chamber installation in no time, saving yourself from costly repairs and ensuring your pipes remain quiet and functional.

Have you tried installing an air chamber in your home? Share your experiences or tips with others, and let’s keep those plumbing systems running smoothly!