In the ever-evolving landscape of modern construction, prefabricated or prefab plumbing systems have emerged as a game-changing innovation, revolutionizing the way we approach residential building projects. For developers and construction managers grappling with tight timelines, budget constraints, and the ever-present demand for quality, prefab plumbing offers a compelling solution that addresses multiple challenges simultaneously. This comprehensive guide delves into the world of prefab plumbing, exploring its myriad benefits, implementation strategies, and the transformative impact it can have on residential construction projects.

The Rise of Prefab Plumbing

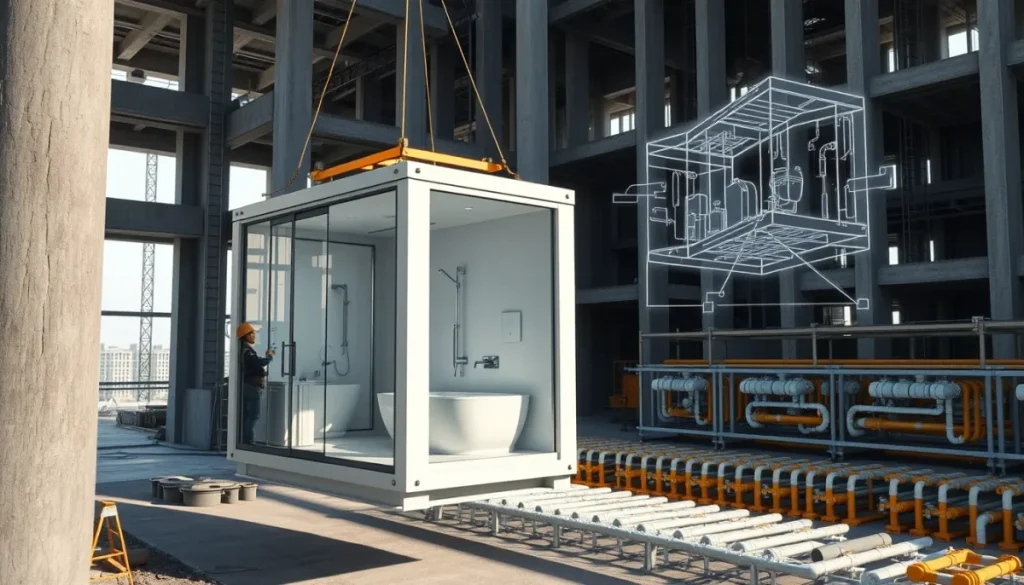

Prefabricated plumbing, often simply referred to as “prefab plumbing,” involves the off-site manufacturing of plumbing components and systems in controlled factory environments. These pre-assembled units are then transported to the construction site for rapid installation. This approach marks a significant departure from traditional on-site plumbing installation methods, offering a host of advantages that are particularly relevant in today’s fast-paced, efficiency-driven construction industry.

Prefabricated building systems can reduce construction waste by up to 90% compared to traditional on-site construction methods. This striking statistic underscores just one of the many benefits that prefab plumbing brings to modern construction projects, particularly in the residential sector where efficiency and cost-effectiveness are paramount.

Streamlining Construction: The Prefab Advantage

Time Savings

One of the most significant advantages of prefab plumbing systems is the dramatic reduction in on-site installation time. Traditional plumbing installation can be a time-consuming process, often subject to delays due to weather conditions, coordination issues with other trades, or unforeseen on-site complications. Prefab plumbing systems, on the other hand, arrive at the construction site pre-assembled and ready for installation.

This streamlined approach can cut installation time by up to 50% compared to conventional methods. For residential projects operating under tight deadlines, this time savings can be the difference between meeting project milestones and facing costly delays. Moreover, the reduced on-site installation time minimizes disruptions to other construction activities, allowing for a more efficient overall project timeline.

Labor Cost Reduction

The efficiency gains of prefab plumbing systems translate directly into labor cost savings. With much of the assembly work completed off-site, the need for skilled labor on the construction site is significantly reduced. This not only lowers direct labor costs but also mitigates the challenges associated with labor shortages, which have become increasingly prevalent in the construction industry.

Furthermore, the controlled factory environment where prefab components are produced allows for more efficient use of labor resources. Workers can specialize in specific tasks, increasing productivity and reducing the likelihood of errors. This efficiency is particularly valuable in residential construction, where labor costs can constitute a significant portion of the overall project budget.

Quality Assurance

Prefab plumbing systems offer a level of quality control that is difficult to achieve with traditional on-site installation methods. In a factory setting, plumbing components are manufactured and assembled under optimal conditions, using standardized processes and advanced equipment. This controlled environment allows for rigorous quality checks at every stage of production.

The result is a consistently high-quality product that meets or exceeds industry standards. For residential developers, this translates to fewer defects, reduced callbacks, and increased customer satisfaction. The precision achieved in the factory setting also means that prefab plumbing systems are less likely to experience leaks or other issues that can be costly and disruptive to rectify post-construction.

Environmental Benefits: Building Greener

Waste Reduction

One of the most significant environmental benefits of prefab plumbing systems is the substantial reduction in construction waste. In traditional construction methods, on-site cutting and fitting of pipes and other plumbing components inevitably lead to material waste. In contrast, prefab systems are designed and manufactured to precise specifications, minimizing excess material.

The U.S. Environmental Protection Agency estimates that construction and demolition debris accounts for more than twice the amount of generated municipal solid waste. By adopting prefab plumbing systems, residential developers can significantly contribute to waste reduction efforts, aligning their projects with sustainability goals and potentially qualifying for green building certifications.

Improved Resource Efficiency

The controlled manufacturing environment of prefab plumbing systems allows for more efficient use of resources. Materials can be sourced and utilized with greater precision, reducing overordering and waste. Additionally, the factory setting enables the implementation of advanced recycling and reuse programs for any waste materials that are generated.

Energy efficiency is another key aspect of prefab plumbing production. Factories can optimize their energy use through efficient lighting, heating, and cooling systems, as well as by implementing energy recovery processes. This level of resource efficiency is challenging to achieve in the variable conditions of a traditional construction site.

Reduced Carbon Footprint

Prefab plumbing systems contribute to a lower carbon footprint in several ways. Firstly, the reduced need for on-site vehicle movements and equipment operation leads to lower fuel consumption and emissions. The precision of prefab components also means fewer material deliveries to the construction site.

Moreover, the efficiency of factory production often results in less energy consumption overall compared to on-site construction methods. For residential developers looking to market their projects as environmentally friendly or achieve green building certifications, the reduced carbon footprint of prefab plumbing can be a significant selling point.

Key Considerations for Integrating Prefab Plumbing

Design Flexibility

While prefab plumbing systems offer many standardized components, it’s important to note that they can often be customized to meet specific project needs. Modern prefab manufacturers work closely with architects and designers to ensure that their systems can accommodate various design requirements.

For residential projects, this flexibility is crucial. Whether it’s a large-scale development with multiple unit types or a custom home with unique design features, prefab plumbing systems can be tailored to fit. However, it’s essential to involve the prefab manufacturer early in the design process to maximize the benefits and ensure seamless integration.

Installation Speed and Coordination

To fully leverage the rapid installation benefits of prefab plumbing systems, proper planning and coordination are essential. This includes:

- Detailed site preparation to ensure smooth installation

- Coordination with other trades to avoid conflicts

- Clear communication of installation schedules and requirements

- Training for on-site teams to familiarize them with prefab installation techniques

When executed effectively, the installation of prefab plumbing systems can be remarkably quick, often completed in a fraction of the time required for traditional methods. This speed can be particularly advantageous in residential developments where rapid occupancy is a priority.

Building Code Compatibility

Ensuring that prefab plumbing systems meet all relevant building codes and regulations is crucial. While reputable prefab manufacturers design their systems to comply with national standards, it’s important to verify compatibility with local codes, which can vary by jurisdiction.

Developers should work closely with local building authorities and prefab suppliers to ensure full compliance. In many cases, the standardized nature of prefab systems can actually simplify the inspection and approval process, as these systems often come with comprehensive documentation and quality assurance records.

Case Studies: Prefab Plumbing Success Stories

Residential Development in California

A large-scale residential development in California implemented prefab plumbing systems across 200 units. The results were impressive:

- Installation time reduced by 40% compared to initial estimates

- Labor costs decreased by 30%

- Material waste reduced by 85%

- Zero plumbing-related callbacks within the first year of occupancy

This case demonstrates the significant time, cost, and quality benefits that prefab plumbing can bring to large residential projects.

Custom Home Build in New York

A high-end custom home project in New York utilized prefab plumbing systems to overcome site access challenges and a tight construction schedule. The outcomes included:

- Complex plumbing systems installed in 50% less time than traditional methods

- Improved coordination with other trades due to reduced on-site plumbing work

- Higher overall build quality, contributing to the home’s luxury positioning

This example illustrates how prefab plumbing can be effectively applied even in high-end, custom residential projects.

Overcoming Challenges and Misconceptions

While the benefits of prefab plumbing are clear, there are some challenges and misconceptions that developers may need to address:

Initial Cost Perceptions

Some developers may be deterred by the perceived higher upfront costs of prefab plumbing systems. However, it’s crucial to consider the total project cost, including labor savings, reduced waste, and faster project completion times. In most cases, the overall cost savings outweigh any initial price premium.

Resistance to Change

The construction industry can sometimes be slow to adopt new technologies and methods. Educating project teams and stakeholders about the benefits of prefab plumbing is essential. Sharing case studies and organizing site visits to projects using prefab systems can help overcome resistance.

Design Limitations Myth

There’s a misconception that prefab plumbing systems limit design flexibility. In reality, modern prefab systems offer considerable customization options. Early collaboration between architects, designers, and prefab manufacturers can ensure that the systems meet specific project requirements without compromising design intent.

The Future of Prefab Plumbing

As the construction industry continues to evolve, prefab plumbing systems are poised to play an increasingly important role. Emerging trends include:

- Integration with Building Information Modeling (BIM) for enhanced design and coordination

- Incorporation of smart technology for improved system monitoring and maintenance

- Advancements in materials science leading to more durable and sustainable plumbing components

- Increased use of robotics and automation in prefab manufacturing, further improving precision and efficiency

These developments promise to make prefab plumbing systems even more attractive to residential developers in the coming years.

FAQs

Q: How much time can prefab plumbing save on a typical residential project?

A: Prefab plumbing can reduce installation time by 30-50% compared to traditional methods, depending on the project’s complexity and scale.

Q: Are prefab plumbing systems more expensive than traditional methods?

A: While upfront costs may be slightly higher, the overall project costs are often lower due to reduced labor, shorter construction timelines, and decreased material waste.

Q: Can prefab plumbing systems be used in custom home designs?

A: Yes, many prefab systems offer customization options to fit various design requirements, making them suitable for both standardized and custom residential projects.

Q: How do prefab plumbing systems impact project sustainability?

A: Prefab systems contribute to sustainability through reduced waste, improved resource efficiency, and a lower carbon footprint compared to traditional plumbing installation methods.

Q: What are the quality control advantages of prefab plumbing?

A: Prefab plumbing components are manufactured in controlled factory environments, allowing for rigorous quality checks and consistent production standards that are difficult to achieve on-site.

Conclusion: Embracing the Prefab Revolution

Prefab plumbing systems represent a significant leap forward in residential construction technology, offering a powerful solution to many of the challenges faced by developers and construction managers. By dramatically reducing installation times, lowering labor costs, ensuring consistent quality, and contributing to sustainability goals, prefab plumbing aligns perfectly with the priorities of modern residential development.

As the industry continues to evolve, those who embrace prefab plumbing systems position themselves at the forefront of efficient, high-quality construction practices. The benefits extend beyond individual projects, contributing to a more sustainable and productive construction industry as a whole.

Are you ready to revolutionize your next residential project with prefab plumbing? Share your thoughts or experiences with prefab systems in your next social media post and join the conversation on modern construction techniques. By engaging with this innovative approach, you’re not just building faster and smarter – you’re shaping the future of residential construction.